As a company, we are starting to see a recurring problem when DALI light fittings fitted with D4i drivers are supplied for a lighting control system.

We are keen to share what we have learned with electrical consultants who may specify or approve the DALI lights, the lighting suppliers, and the electrical contractors who may be installing them.

This knowledge may help prevent costly mistakes in future installations.

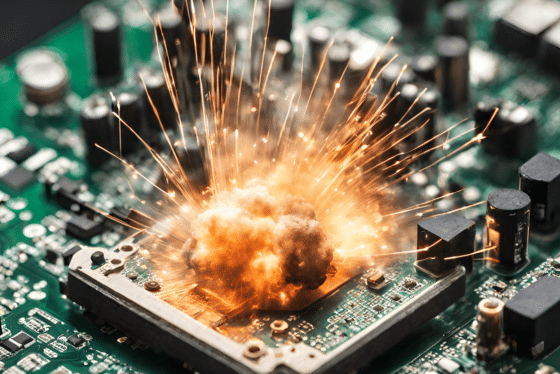

Below, therefore find, in good faith, the information that we hope will avoid blowing up the next lighting control system you’re involved with!

Please note:

This information is taken from our experience only. We are not involved in the manufacture of lights, drivers or associated equipment, and do not profess to be ‘experts’ in this area whatsoever.

However, the circumstances we have recently seen, and subsequent finger-pointing as to who should pay for the costly replacement of controls equipment damaged as a result, prompts us, in good faith, to share what we have learned, in the hope that it may assist all parties involved in the design, specification and supply of lighting and controls systems.

D4i Drivers

D4i is a standard for LED drivers that represents an evolution of the DALI (Digital Addressable Lighting Interface) protocol, specifically tailored for LED technology. DALI is a widely used communication protocol in the lighting industry, designed for easy and efficient management of lighting systems. The “i” in D4i stands for “intelligence,” highlighting the enhanced capabilities for smart, connected lighting solutions.

As above, D4i is provided as an extension of the DALI-2 certification program. D4i LED drivers have a mandatory set of features related to power-supply requirements and smart-data capabilities.

One of the key criteria within the specifications is the MANDATORY integrated bus power supply. The theory behind this is to simplify the installation and reduce the need for additional components when a full lighting control system is not supplied.

A key point is that within the certification standard the integrated bus power supply must have its default set to ON.

This is when things become a little sticky, when the lights fitted with D4i drivers are supplied to be part of a lighting control system.

DALI-2 Systems + D4i Drivers

The DALI bus carries DALI power and data on the same pair of wires. Each DALI subnet can have 64 control gear and 64 control devices. A bus power supply is required, providing up to 250 mA and typically 16V to the DALI bus.

When a lighting controls provider supplies a DALI-2 solution they will always incorporate into their design the necessary DALI power required to operate the control gear and control devices. When the lighting controls design proposal is submitted and approved, it is very likely that although DALI lights are specified, there is no knowledge as to the drivers that will be supplied.

When d4i drivers are supplied integral with the light fittings, to ensure the DALI bus power does not exceed the allowed 250mA, the integrated PSU of the driver must be OFF. If the d4i driver PSUs are permitted to remain on the DALI bus power will be exceeded, and controllers and other devices installed on the DALI line will be damaged.

Whose Responsibility?

When the luminaire specified does not include detail as to the type of driver then on whom should responsibility fall

- to ensure the driver is DALI compliant, and

- to ensure that if a D4i driver is to be used, that the luminaire provider supplies the driver with the PSU off?

It is not uncommon for even the lighting supplier to be unaware of the type of driver that has been incorporated into their fittings.

With our zencontrol software, a benefit has been the ability to identify where non-compliant drivers have been supplied, and the painful exercise of replacing them with compliant drivers has then had to be undertaken by the lighting supplier or the electrical contractor.

However, with the issue of extra power being introduced to the DALI line by the PSUs of the D4i drivers, the software check is not possible, as the damage has already been done when all devices are initially connected to the DALI line.

Our Recommendations

- Ensure your Lighting Controls Supplier/Integrator has been provided with the details for the DALI drivers for the light fittings.

- Before connecting the DALI-2 system PSU, the DALI line MUST be checked for voltage by the installing electrician. There should be no voltage present! If there is, it is likely the D4i drivers are present, with the PSUs on, and putting power on to the DALI line.

- Ensure the issues are FULLY RESOLVED, before the DALI PSU is connected, or the DALI controllers will be DAMAGED BEYOND REPAIR.

This issue obviously has significant ramifications for all those involved in the lighting industry.

If you’d like to talk through any of the points covered, or have any questions, we are always happy to advise. Please give us a call.